Cadent Gas

Auto Utility - Automated Pipeline BIM Modelling and Cost Estimating Tool

Project Background

Cadent Gas, formerly known as National Grid Gas Distribution Limited was part of National Grid plc until 31 March 2017. Cadent is Britain's largest gas network and maintains 131,000 kilometers of pipes supplying 11 million homes in the North West, Midlands, East and South East of England.

To deliver Cadent’s license obligations as a Gas Distribution Network operator, there are a large number of >7bar steel pipeline diversions, network reinforcements and customer driven diversions to be designed and constructed.

The specialist design and cost estimating resources required to design and estimate the costs of these works was provided through a transitional agreement that finished in 2017. Cadent lacked the in-house resources to deliver these specialist requirements making Cadent wholly dependant upon external resources.

Challenge

To address the challenges and issues noted above Cadent Gas initiated a Network Innovation Allowance (NIA) project to develop a “first of its kind” automated design and cost estimation application. The software application would allow Cadent to develop conceptual designs utilising in-house engineering resources, respond to customer enquiries in a much shorter timescale reducing customer response times from months to weeks, and automate the production of conceptual design reports at a fraction of the current costs.

Key Requirements:

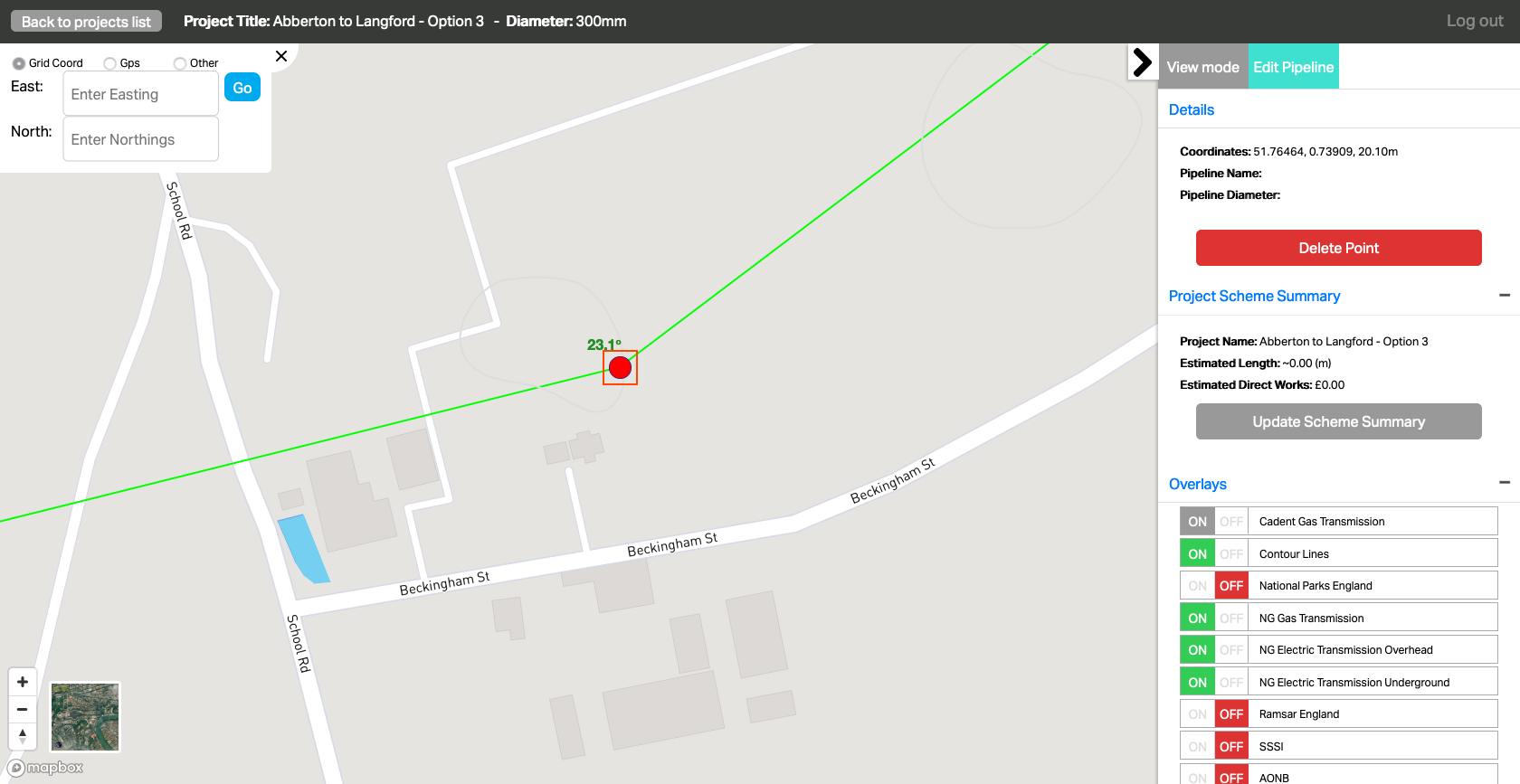

- Allow engineers to route a new pipeline / diversion through an interactive mapping interface

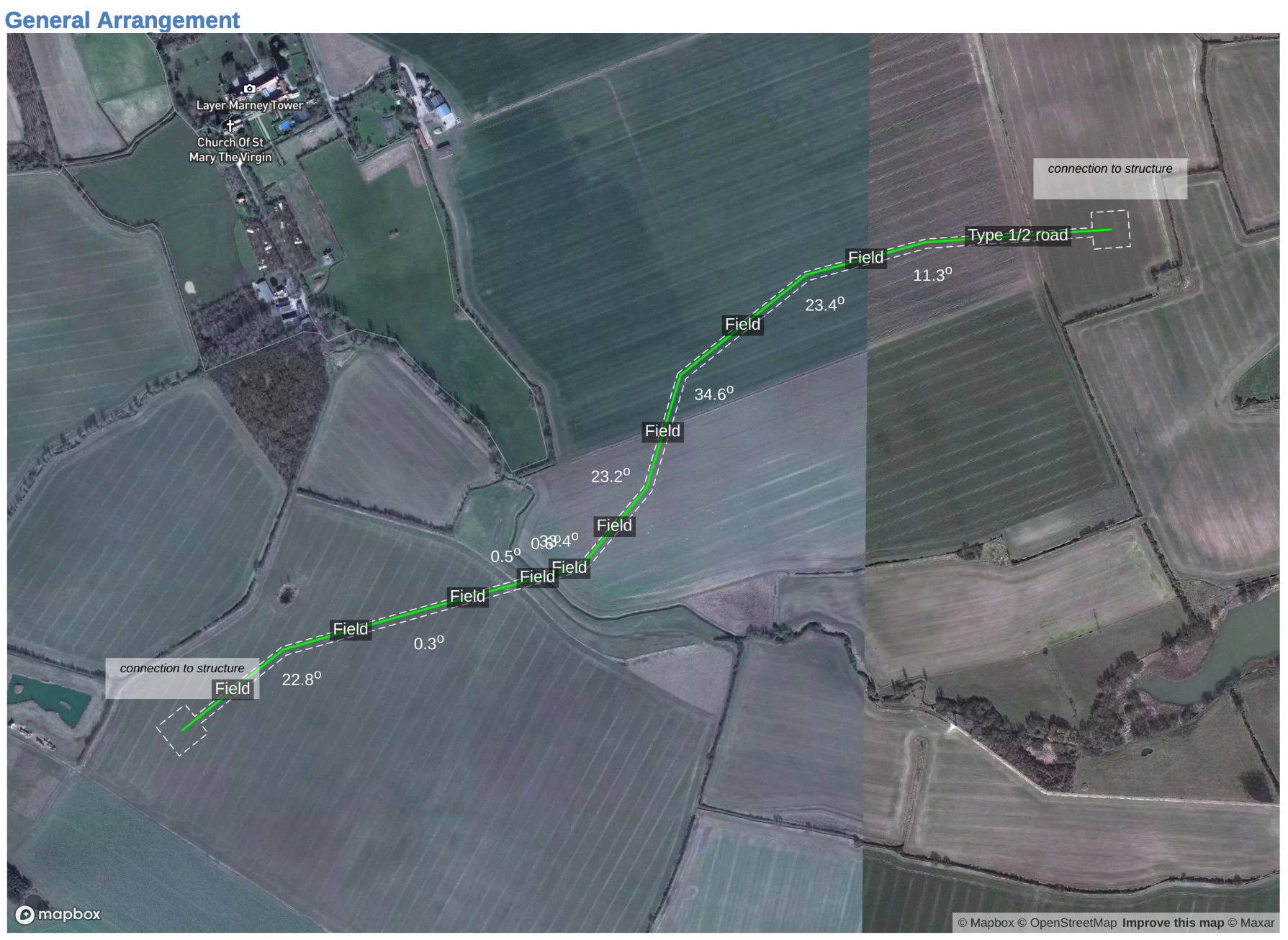

- Automatically design a scheme, based on a user's routing, in accordance with all applicable design codes

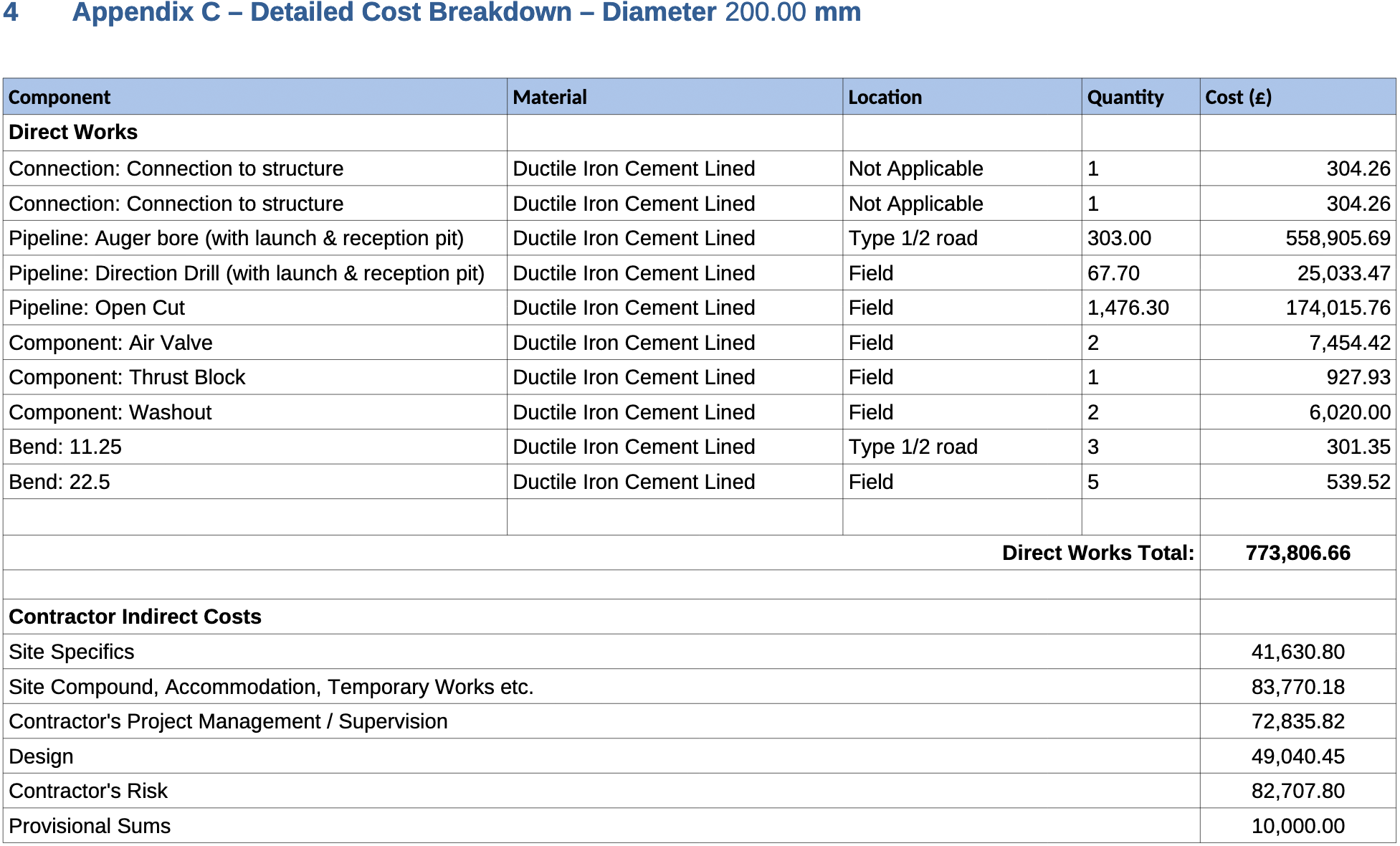

- Generate cost estimates based on the design outputs within a margin of +/- 25%

- Automatically produce a 3D graphical representation of the designed scheme in a standard BIM format

Solution

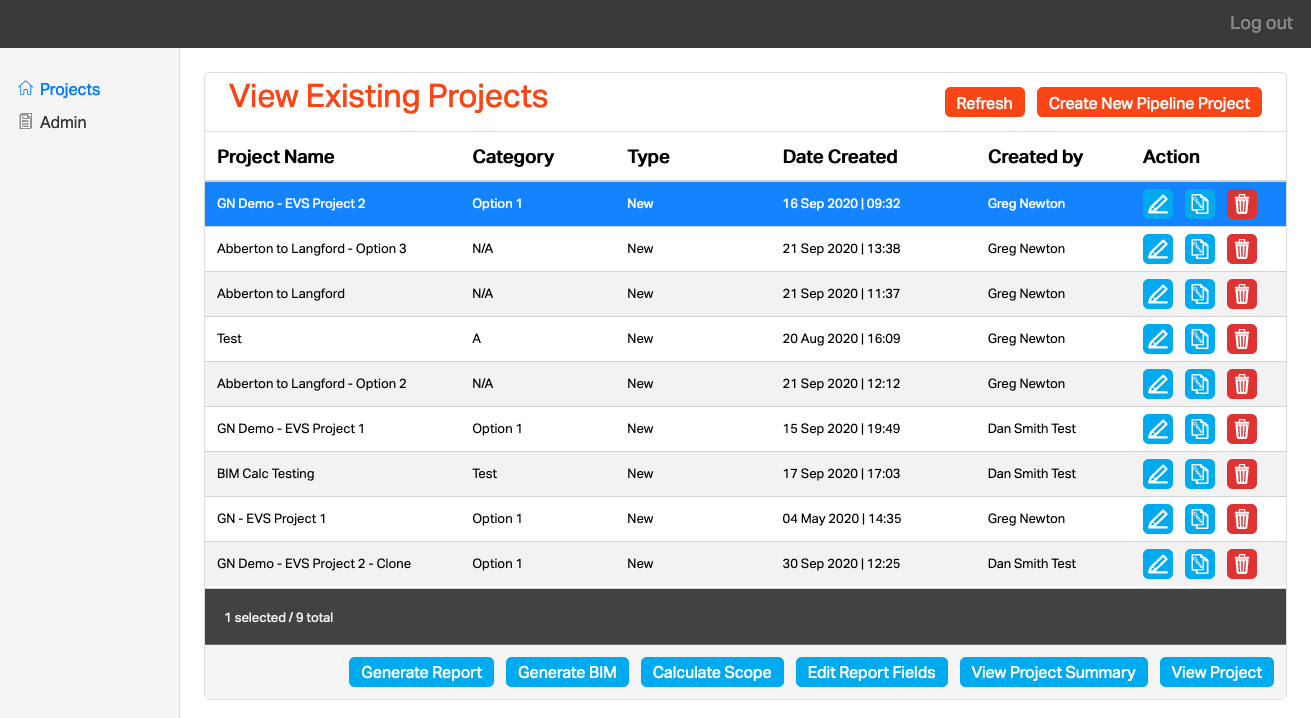

The meet the requirements of the project the Auto Utility platform was developed as a collaborative web application. Access was provided as Single Sign-On by integrating with Azure Active Directory allowing Cadent staff to access the system using their standard network accounts. The interactive mapping interface was developed using the MapBox GIS API allowing for real-time streaming of Ordnance Survey and Satellite imagery.

The Auto Utility portal functionality includes generating a 3D BIM model of the final pipeline design, automatically creating a Conceptual Design Study (CDS) report, and centrally storing all relevant project information in a collaborative cloud-hosted ECM platform. Due to the vast differences in hosting requirements between the 3D BIM generator and the rest of the application's functionality the architecture was designed as a series of microservices to be hosted in a public cloud platform. This allowed for per-service scaling and ensured that long-running background tasks such as the generation of the BIM model did not impact the performance of the rest of the app.

Historically the design and cost estimation process for >7bar steel pipelines and diversions required the engagement of external design and cost consultants. Dependent upon the complexity and size of the project, each scheme can take between 3 months and 12 months to develop a conceptual design report (CDR) which costs between £50,000 and £250,000.

Auto Utility was developed to automate the creation of the CDR allowing for a months-long process to be completed in seconds. This was accomplished by integrating complex engineering calculations in to the system using a C++ service module that would do a breakdown of all required pipeline components and produce a bill of quantities and an overall project cost. The output from this costing service was fed in to a PDF generator that used OpenOffice document templating to generate the final report.

The web application was developed using Angular 2.0+ with back-end API services developed in Node using the Express framework. More complex services such as the BIM generator were developed natively in C++ and integrated using Node Gyp - Node's native addon build tool. Microsoft SQL Server was used for the platform's databases.

Auto Utility was developed to run in Amazon Web Services using OS-level virtualisation through Docker. It continues to be maintained using a suite of automated tests and deployments through a Continuous Integration / Deployment pipeline.